“Specialized in mould manufacturing for automotive plastic injection moulding parts”

An ISO 9001-2015 certified organization located in Mumbai, India. The company commenced its humble beginnings in the year 2001, and within a short span, developed into a modern technological business centre, ensuring high-quality tooling in the field of mould manufacturing. Specializing in plastic mould products and pressure die casting moulds, we offer a comprehensive suite of services — from design, mass production, assembly, to testing — all under one roof. With over 25+ years of experience, we have consistently delivered precision-engineered solutions that cater to a wide range of industries. What sets us apart in a competitive market is our commitment to innovation and our proactive investment in cutting-edge technologies. Unlike many of our competitors who often stick to conventional methods, our team of skilled engineers continually adapts to the latest advancements, enabling us to deliver highly customized and efficient mould solutions.

What we offer

Our Best Moulds

PHARMACEUTICAL MOULD

Used to make medicine bottles, caps, syringes, and other sterile parts. Ensures hygiene, accuracy, and quality required for pharmaceutical and medical applications.

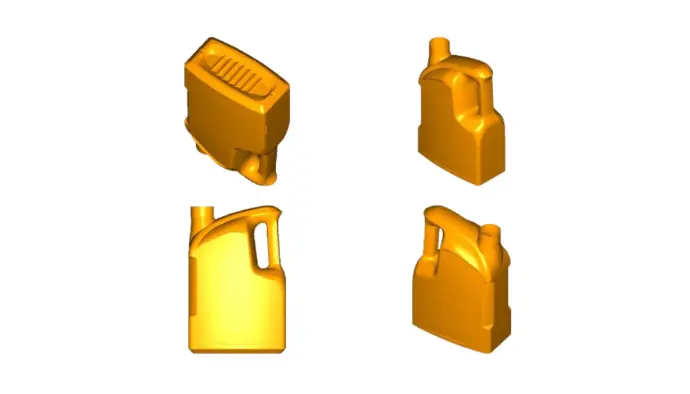

AUTOMOBILE MOULD

Developed for vehicle parts like bumpers, dashboards, and engine covers. Ensures strength, precision, and consistent quality in high-volume automotive production.

DIE CASTING MOULD

Designed for shaping molten metals like aluminium or zinc into precise, durable parts. Commonly used in automotive, electronics, and machinery for producing complex metal components.

ELECTRONIC MOULD

Used for creating casings and components for electronic products with high accuracy. Ensures perfect fitting, clean finish, and safety for electrical or electronic devices.

LUGGAGE ACCESSORIES MOULD

Creates parts like wheels, handles, locks, and frames for luggage and travel gear. Built for long life, perfect fit, and smooth operation under regular use.

AGRICULTURAL MOULD

Used for tough, outdoor farm equipment parts like flat dripper, round dripper, pipes, and tool covers. Designed to resist heat, chemicals, and weather for long-term performance.

TOY ITEM MOULD

A toy item mould is a custom tool, typically used in the plastic injection molding process, to shape liquid plastic into a specific toy design. The mould has two halves—a core and a cavity—which together create a negative of the toy's shape.

BLOW MOULD

Used to make hollow plastic items like bottles and tanks with uniform thickness and strong structure. Ideal for packaging and industrial containers needing high strength and light weight.

ALL KINDS OF ENGINEERING MOULD

We also make all types of moulds for plastic and die casting components across industries. Focused on precision, durability, and efficient production from prototype to final part.

OUR TEAM

All the departments are headed by qualified and trained professionals with adequate experience in respective fields.

Our Vision & Mission

To build a world class company Preferred supplier to global customers Rapid adaptation to the latest technologies.

OUR COMPANY PROCESS CHART

OUR PRODUCTS

Kamiliant And Tommy Hilfigher Bag Handle

Disposable Skin Stapler

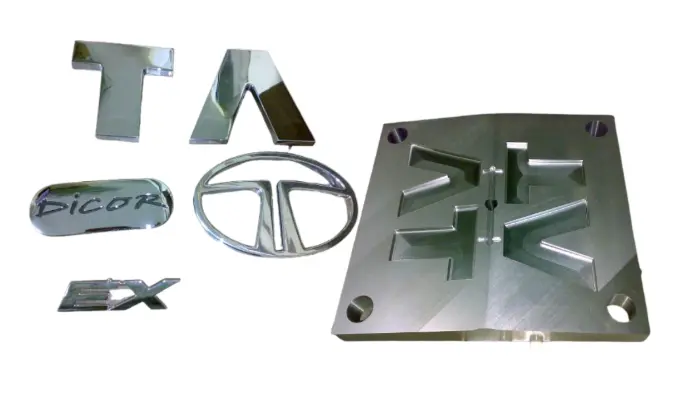

TATA Logo

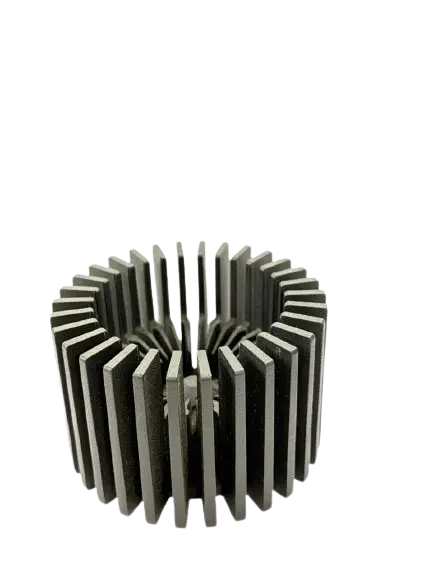

Aluminium Heat Sink

Chain Sprocket

American Tourister Luggage Bags Handles

Pump Housing Or Casing

Luggage Bags Accessories

American Tourister Logo

Pump Impeller

Dental Impression Tray

Plastic Dental Cartridge

Associated Brands

Brands that we nurture

Why work with us?

Expertise in engineering thermoset and thermoplastic products.

Right technical fit

Our engineering expertise is to process and manufacture universal plastic products. Choose us for a technically satisfied project execution.

Equipped right

Equipped with machineries to cater all your compression moulding and injection moulding projects.

D2P-(Dev-to-Prod)

Convert any drawing into product with our one stop solution for engineering plastic products with mold manufacturing and molding.

Beating your competition

JCME helps you stay ahead of your competition by reducing go to market time and saving money on development cost.

jaychamunda_999@yahoo.com

+91 8459178360